The insulating joint is the essential pressure component necessary for steel pipeline cathodic protection system, broadly applicable to steel pipeline cathodic protection systems. Our company's insulating joints adopts a unique design as per ASME VIII- 1, Appendix 2 standard and ASME B31.3 code, based on referencing foreign latest product structure to overcome problems of inadequate rigidity, prone to leak, unable to be buried under ground short service life, etc. The insulating joints have realized buried intenance-free function and allow a service life matching the pipelines.

The insulating joint is the essential pressure component necessary for steel pipeline cathodic protection system, broadly applicable to steel pipeline cathodic protection systems. Our company's insulating joints adopts a unique design as per ASME VIII- 1, Appendix 2 standard and ASME B31.3 code, based on referencing foreign latest product structure to overcome problems of inadequate rigidity, prone to leak, unable to be buried under ground short service life, etc. The insulating joints have realized buried intenance-free function and allow a service life matching the pipelines.

Technical characteristics

| Design code | ASME VIII-1, Appendix 2 and ASME B31 3 |

| Dimension specification |

DN15-DN3000 |

| Design pressure | 1.0-40MPa |

| Service life | Same as the service pipeline |

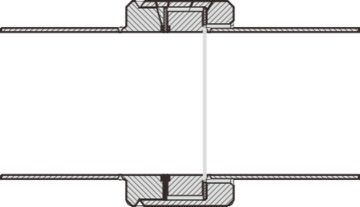

Product structure

Testing and inspection standard

Testing and inspection standard

* Hydraulic pressure testing with 1.5

times of designed pressure

* AC3000V applied voltage test

* DC1000V insulating resistance value test

* Visual check

* Dimension check

* 5% the hydraulic added bending test

* 5% the hydraulic circulation (fatigue) test

* 5% submerging electrolysis fluid insulting intensity testing

* 5% the thickness of coated dry velum test